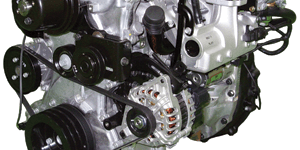

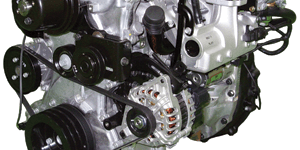

Engine

HIGH-PERFORMANCE HYUNDAI THETA LPG ENGINE

The 4-cylinder, dual overhead cam engine produces 52 HP and 114 ft-lbs of torque @ 1500 rpm for superior performance.

Internal, self-lubricating chain-driven cams and automatic chain tensioner provide long-life and protection from debris.

Brake System

SIMPLE & ERROR PROOF

Foot applied brake can be released by hand or foot

Transmission disengages when parking brake is set preventing driving against brakes

Horn will sound if brake is not set after 3 seconds

Hydraulic System

MAXIMUM HORSEPOWER

Uses load-sensing flow control valve to reduce heat build-up

OPTIMUM PERFORMANCE OF ATTACHMENTS

Main hydraulic valve incorporates adjustable flow controls for tilt and auxiliary functions

SECTIONAL DESIGN

Allows for easy addition of extra functions and simplifies service

UPRIGHT MOUNTED LOAD LOWERING VALVE

Controlled lowering independent of engine speed

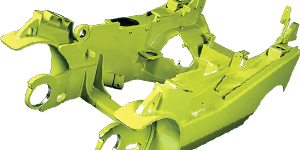

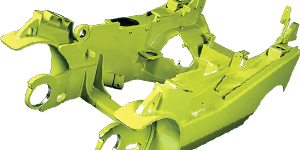

FRAME

ONE PIECE FRAME

Heavy duty, welded & formed steel plate protects from impact damage and extends the life of the truck

An integral hydraulic sump, with remote breather provides cooling for hydraulics in tough applications

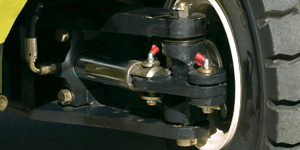

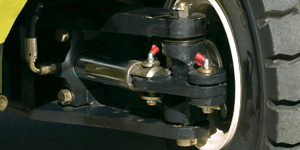

Steering Axle

RUGGED "DOUBLE SHEAR" DESIGN

To withstand impact without loosening or breaking

SIMPLE, DOUBLE-ENDED CYLINDER DESIGN

Provides additional steering force

Dash Display

MICROPROCESSOR

Monitors condition and controls function of truck systems

Controls neutral starting and prevents cranking while engine is running

LCD DISPLAY

Hourmeter and maintenance intervals are displayed

LED LIGHTS INDICATE

Transmission temperature

Engine oil pressure

Alternator charge

Fuel system malfunction

Park brake applied

Maintenance required

Seat belt

PUSH SWITCHES

Headlight and optional worklights are controlled with push switches

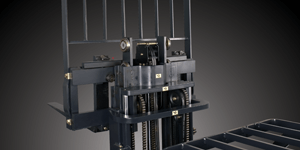

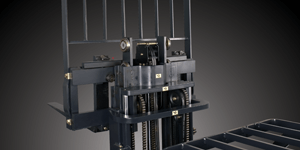

Upright & Carriage

MAXIMUM VISIBILITY

Nested I-channel allows space for cylinders, hoses and chains

HYDRAULIC CUSHIONING VALVE

Silent staging reduces shock and vibration

SHIMMABLE, SEALED & CANTED ROLLERS

Carriage has 6 rollers to maximize load distribution and reduce free play

Operator Compartment

OPTIONAL FULLY ADJUSTABLE, FULL SUSPENSION SEAT

Molded for support with non-cinching, retractable seat belt

TILT STEERING COLUMN

Adjust to suit operator and provides easier entry/exit

COWL MOUNTED HYDRAULIC CONTROLS

Located and sized for ease of use

THICK MOLDED FLOOR MAT

Reduces vibration and noise level to improve operator comfort