Drive Unit

QUIET, LOW MAINTENANCE OPERATION

Spiral bevel gears are immersed in an oil bath and sealed in a heavy-duty case

HEAVY DUTY BALL BEARING ABLE TO ENDURE HIGH SHOCK

Hydraulic System

SINGLE ASSEMBLY SYSTEM

The integral pump, motor and reservoir assembly does not require a breather cap eliminating a potential leak site and point where dirt can enter the system.

Ac Drive Motor/Control

FULLY ENCLOSED

Keeps out dust and contaminants

Wet environment is not an issue

Better suited for food processing

NO BRUSHES TO CHANGE OR COMMUTATOR TO TURN EVER

Routine brush changes are eliminated

No need to pull the motor to turn and undercut the commutator

Much less likely to burn-out motor during a stall

THREE FORMS OF REGENERATIVE BRAKING

Change of direction

Accelerator Release

Tiller Up or Down

ADVANCED THERMAL PROTECTION

Prevents heat damage to the motor and control

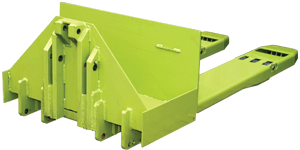

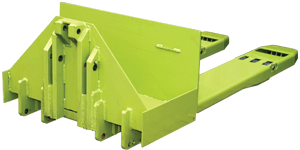

Rugged Frame & Forks

Frame is fabricated from formed steel plate and bar steel reinforcements for optimum strength and rigidity.

Forks also incorporate formed steel toes plus entry and exit rollers for improved pallet handling.

Lifting Mechanism/undercarriage

PULL RODS

Adjustable to maintain proper fork height over the life of the unit

Constructed from steel bar stock for maximum strength and durability

BRONZE BUSHINGS

Extreme-duty bronze bushings are used at lift linkage pivot points

SPRING-LOADED STABILITY CASTERS

Maintains contact on uneven surfaces

ELEVATION BRACKETS

Three-lug design reduces binding and promotes longer pin and bushing life

All pivot points are greaseable and feature steel backed bushings

Steer/Control/Handle

OPERATOR CONTROL

Handles are available with either twist grip or thumb operated control

TOGGLE SWITCH

Allows the operator to choose low or high speed range based on the application

MINIMAL STEERING EFFORT

Low mounted steer handle on the PWX provides increased leverage

AMPLE FOOT ROOM ON RIDER PLATFORM

Top mounted handle on HWXE

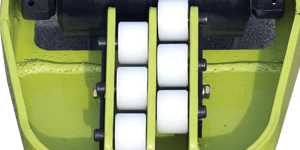

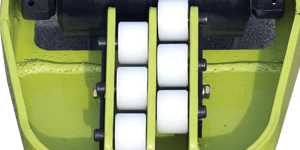

Pallet Entry/Exit

Entry and exit rollers plus tapered slides improve pallet entry and exit